Brigida González

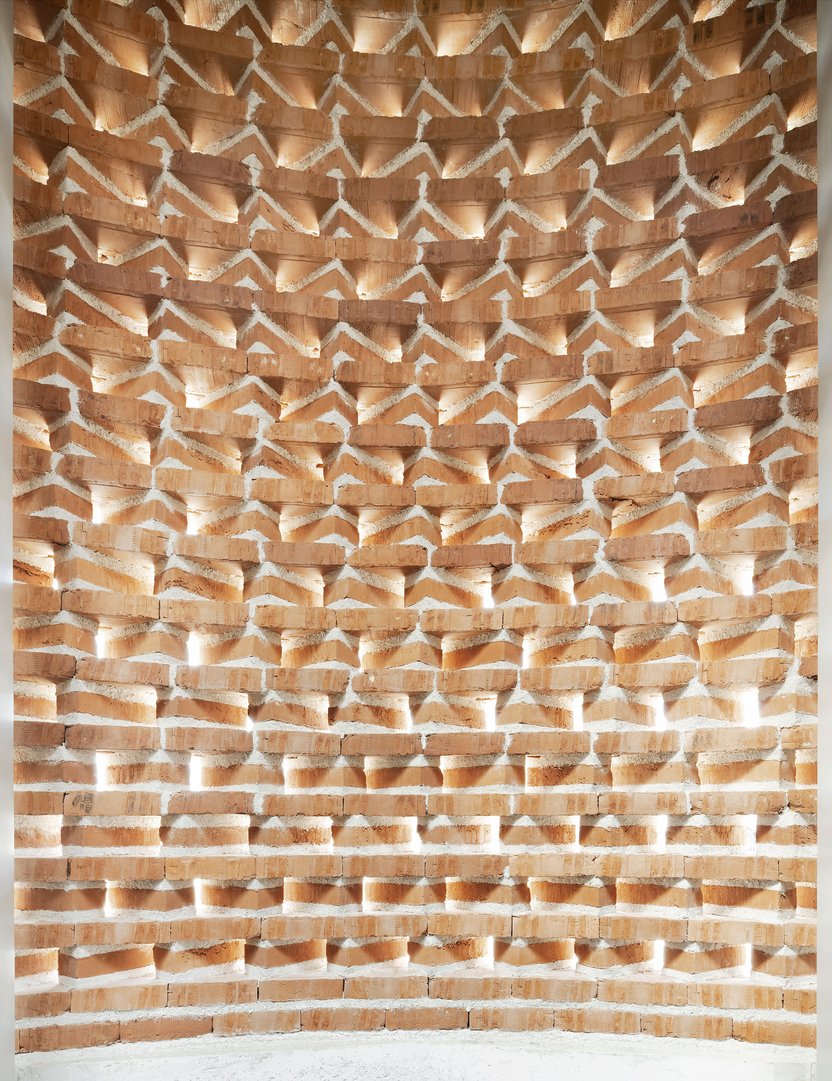

Construction and assembly In addition to the advantages of the rear-ventilated clinker facade in terms of thermal performance and moisture management, many interesting, subtle details pose a challenge for modern architecture. The format of the bricks and the size of the mortar joints were chosen as a subtle reference to Roman construction methods. The Romans built the road along the Neckar River as a transport route between Heidelberg and Ladenberg. The wide joints were the maximum possible without the use of support grains, which would have made the construction of the clinker facade more expensive and time-consuming. The texture of the bricks was chosen to contrast with the smooth, monolithic appearance of the prefabricated concrete roofing and base elements. As there was no budget for wire-cut clinker bricks, a standard brick pattern was examined, which revealed that the back of the bricks had a rough surface. This is due to the bricks being stored during the drying process. Turning the bricks over was a cost-effective way to make the masonry appear more robust and resilient. This roughness is further enhanced by the broken light and shadows cast on the rounded ends of the building. At the rear of the technical building, a closed outdoor area is required for the heat pumps that cool the data center. In order to conceal the mechanical equipment and at the same time ensure the air circulation required for the heat exchangers, it was necessary to design the brick formats as a ventilated privacy screen. This was achieved by constructing a “Wythe wall” with alternating diagonal rows laid with gaps. The masonry appears openwork and filigree. Conical steel supports carry the concrete roof slab cast on site, and the brick screen is self-supporting due to its geometry. There are various ways to bridge openings in the rear-ventilated clinker facade. Here, we opted for a prefabricated concrete lintel with vertical clinker, with the prefabricated elements extending beyond the width of the door opening to create the visual impression that the loads are supported by pilasters on both sides of the openings. These quasi-pilasters have the necessary working joints. They prevent cracks caused by the expansion and contraction of the facade. These joints are sealed with silicone, the color of which matches the shade of the mortar joints as closely as possible. An additional measure to harmonize these joints with the rest is to sprinkle the wet joints with sand that matches the material of the mortar. The typical wall construction between precast concrete elements consists of a load-bearing core of reinforced concrete, mineral wool insulation, a rear-ventilated cavity, and an outer skin of solid masonry. Since the location near the water encourages all kinds of animals to nest in artificial cavities, the ventilation openings at the lower and upper levels of the masonry are fitted with stainless steel butt joint ventilators – known as “bee biters.” This façade is framed by continuous rows of bricks. This keeps it flush with the concrete canopies and the base around the entire perimeter of the building. In combination with the oversized horizontal mortar joints, the building takes on a simple, monolithic cubature. The actual dimensions of the building are difficult to gauge. From a distance, two rather standard-looking shapes can be seen. Upon closer inspection, the actual dimensions of the building become apparent, surprising in height, depth, and width.

Ecker Architekten